Agriculture

To support the safe and reliable production and storage of food, the agriculture industry depends on a wide range of concrete and steel infrastructure.

NDT Corporation provides testing and evaluation services for agricultural structures, including silos and food processing facilities. The data Silcollected supports maintenance planning and rehabilitation efforts led by owners and engineering teams.

Deterioration of Silo Structures

Silo structures are widely used in agricultural to store various products. Many existing silos experience age-related deterioration or deferred maintenance, which can lead to operational disruptions and safety concerns.

A common challenge with silo structures is the absence of original construction drawings, resulting in limited documentation of wall thickness, reinforcement layout, and material properties. Non-destructive testing methods, such as ground penetrating radar (GPR), are used to document wall thickness and reinforcement configuration where records are unavailable. Slip-form construction methods often result in non-uniform reinforcement, making field verification particularly important.

Concrete thickness, reinforcement layout, and compressive strength data collected through testing can be used by engineers to support evaluations related to structural capacity. In addition, the repeated filling and emptying of silos subjects walls and roofs to varying stress and loads, which may contribute to cracking, wall deterioration, or roof distress. In some cases, roof movement or bearing issues may also develop over time.

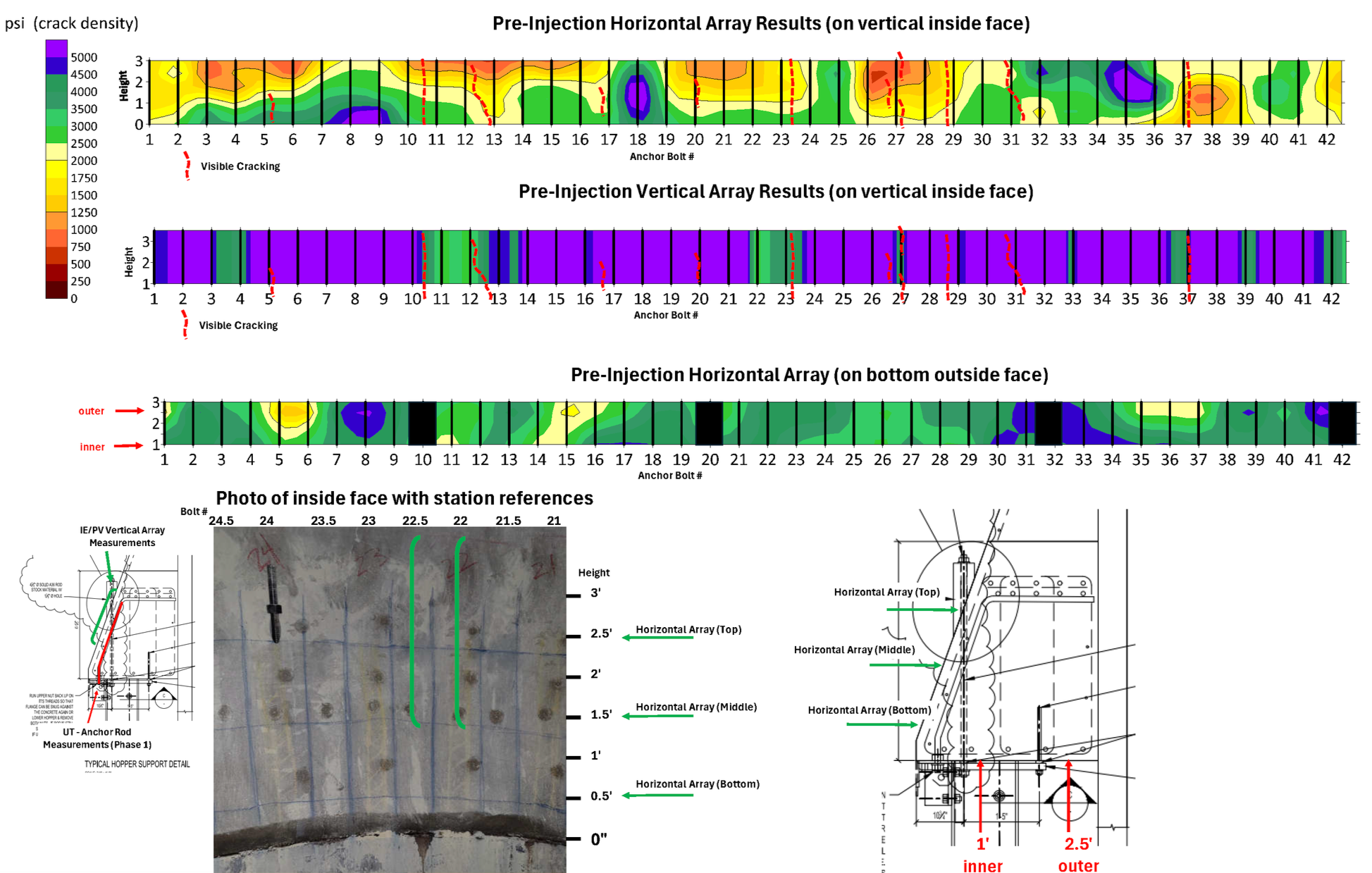

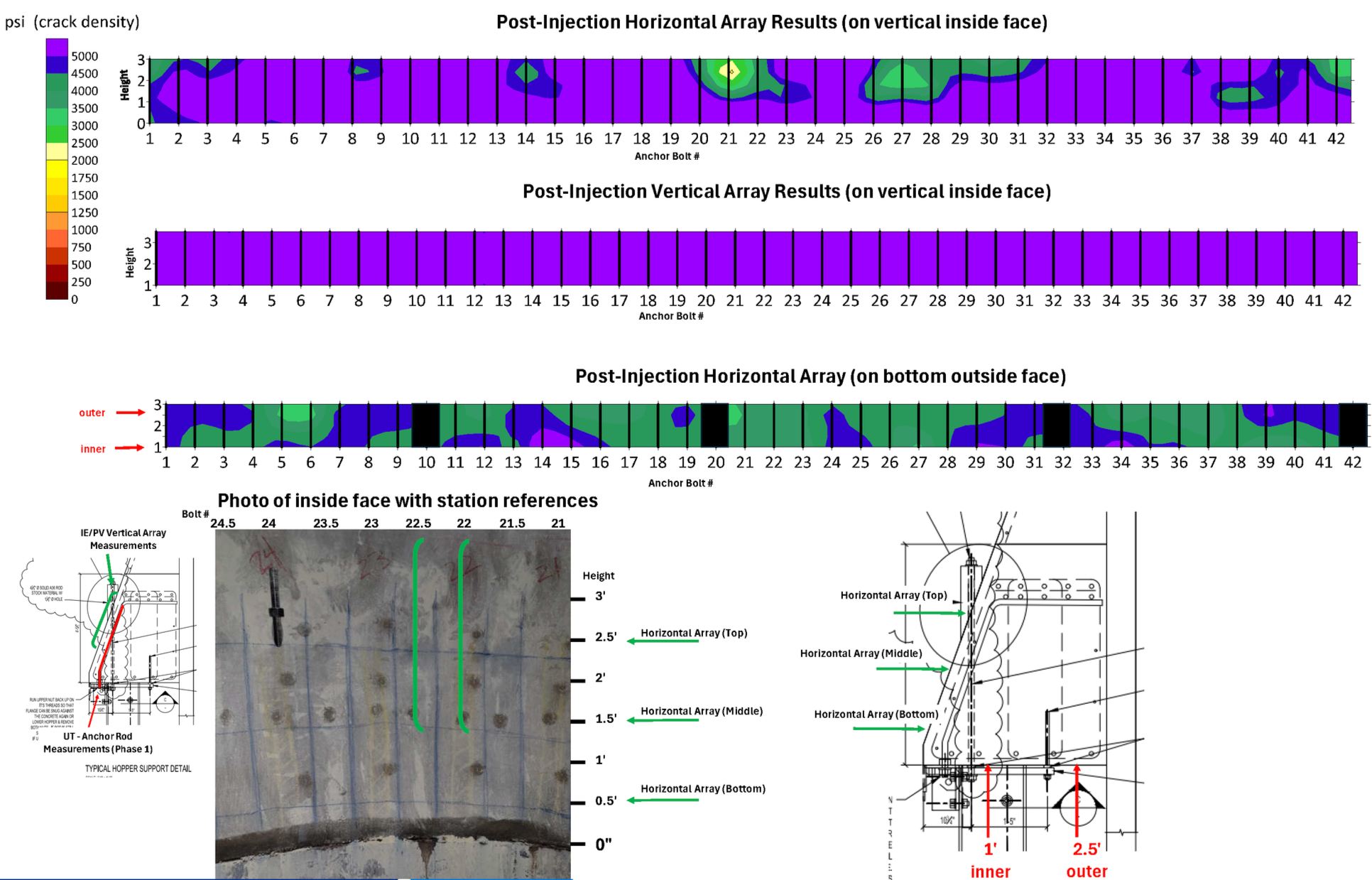

Impact echo and pulse velocity (IE/PV) testing can be used to collect data on the condition of silo walls, floors and roof elements, including indications of cracking or internal deterioration. This information supports owners and engineers when planning inspections, repairs, or rehabilitation activities.

Corrosion in Food Processing Facilities

Food processing and manufacturing facilities often operate in aggressive environments that can accelerate material deterioration. The use of heat, moisture, and processing chemicals associated with agricultural production can create conditions that are highly corrosive to reinforced concrete and steel elements.

NDT Corporation provides testing services to document material conditions and corrosion-related indicators within these facilities, supplying data that can be used by project teams to understand deterioration mechanisms and support durability-related decision-making.

Our IE/PV testing is often used as a QA/QC process to assess the quality of a repair operation. By collecting data before and after a repair project such as a crack injection repair project the effectiveness of the repair can be quantified.

Experience You Can Rely On

Founded in 1994, NDT has built a reputation for delivering reliable data, practical insight, and responsive service on technically complex projects. Our team combines decades of field experience with advanced testing technologies to produce results that are clear, defensible, and actionable for engineers and owners.