Prestressed and Post-Tension Inspection

Our experts will help you determine which methods are most effective and economical for your needs.

METHODS

Grout Void and Defect Identification

Inspection of Internal Post-Tensioning

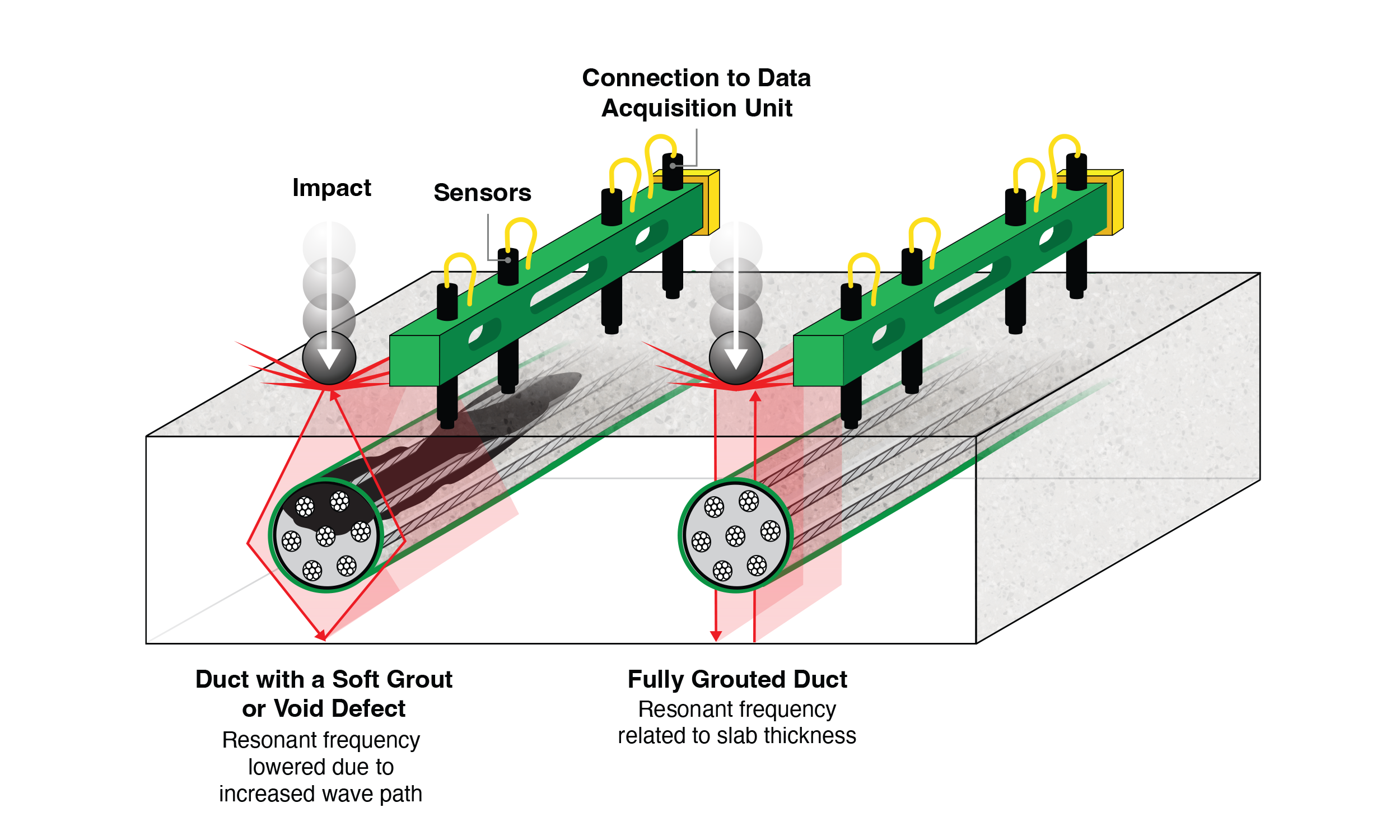

The condition of internal post-tensioning (PT) tendons can be investigated using the acoustic testing method Impact Echo (IE). IE testing evaluates the response of stress waves introduced near the PT duct to identify changes associated with grout conditions.

IE measures the resonant frequency response of the system. When voids or soft grout are present within a PT duct, the wave travel path and material response are altered, resulting in a measurable reduction in resonant frequency. By collecting IE measurements along the length of a PT tendon, variations in resonant frequency can be used to identify locations where grout defects may exist.

Inspection of External PT

Pulse Velocity (PV) testing can be used to examine external post-tensioning tendons for potential grout defects. The method involves placing a wave source and receiver on opposite sides of the tendon duct to measure stress wave transmission.

Changes in the recorded pulse velocity signal may be associated with grout conditions such as voids, water, or soft grout within the duct. PV measurements collected along the tendon length provide data that can be used to identify locations where grout characteristics differ.

IE/PV testing of internal PT tendons on a bridge.

Borescope Inspection

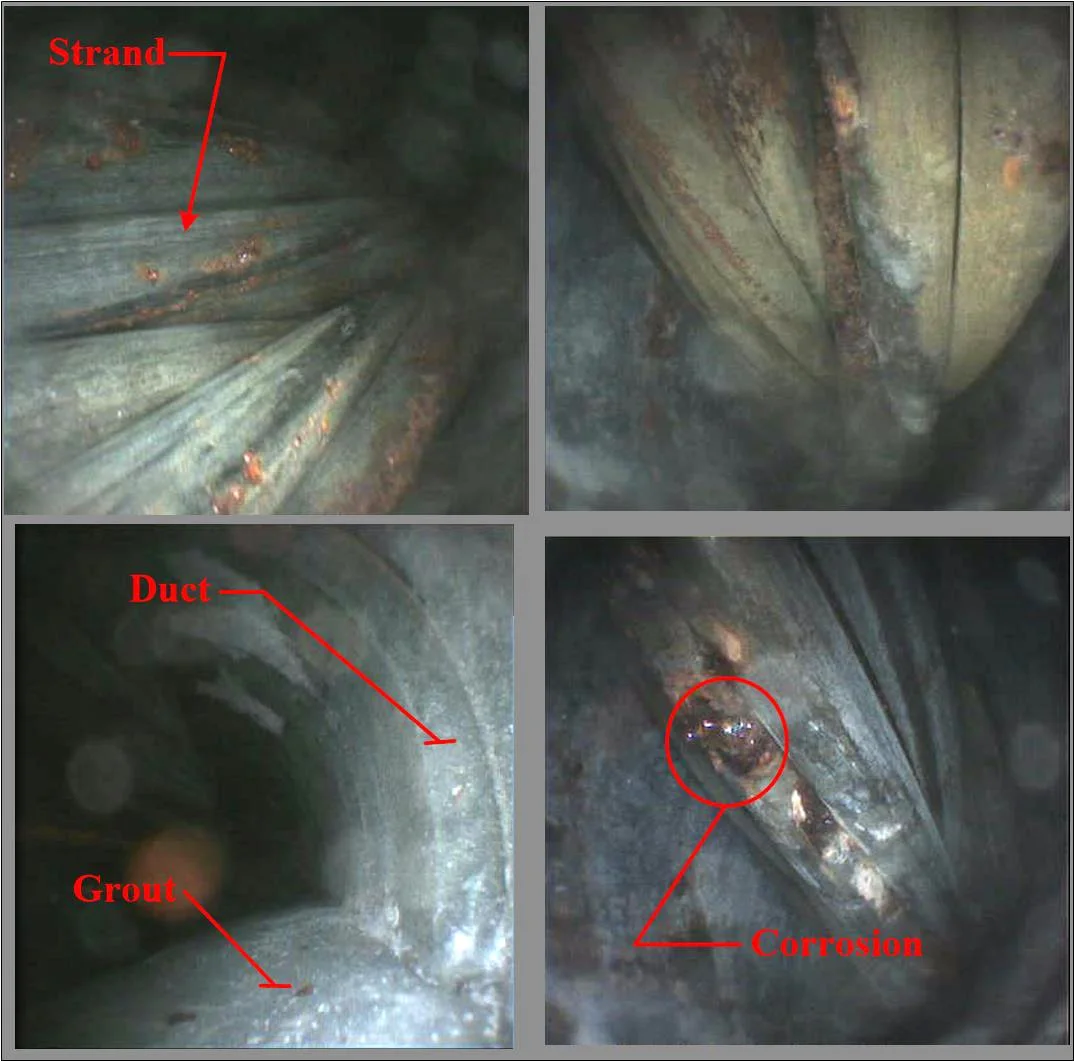

Once potential post-tensioning (PT) grout anomalies such as voids or soft grout have been identified through prior testing, access points can be created in the tendon duct to allow for borescope inspection. This typically involves drilling a small opening to insert the borescope and visually observe internal conditions.

Borescope inspection provides direct visual documentation of grout conditions within the duct while minimizing physical disturbance to the PT system.

In cases where grout conditions warrant further examination, larger access openings may be created to obtain grout samples for laboratory analysis, based on project requirements.

Acoustic Inspection Methods

Acoustic inspection of concrete pipe is performed using Impact Echo and Pulse Velocity (IE/PV) testing. This approach measures compressional and shear wave transmission velocities to document mechanical characteristics of the concrete.

When applied along a pipeline, IE/PV testing can be used to identify sections exhibiting changes in wave response that may be associated with reduced wall thickness or a loss of pre-stressing force. The collected data provides objective information that owners and engineering teams can use to support asset management activities and reduce the risk of unexpected pipeline failures

Experience You Can Rely On

Founded in 1994, NDT has built a reputation for delivering reliable data, practical insight, and responsive service on technically complex projects. Our team combines decades of field experience with advanced testing technologies to produce results that are clear, defensible, and actionable for engineers and owners.