Concrete Material Testing

Our experts will help you determine which methods are most effective and economical for your needs.

METHODS

Carbonation Depth

Carbonation depth testing is used to measure how far carbonation has progressed into concrete. As carbon dioxide enters moist concrete, it reacts with the cement paste and reduces the concrete’s pH. When carbonation reaches the level of the reinforcing steel, the pH of the concrete surrounding the steel is lowered, reducing the protective environment that normally limits corrosion.

Once this protective condition is lost, reinforcing steel becomes susceptible to corrosion in the presence of moisture and oxygen.

Carbonation depth measurements are commonly compared with the depth of reinforcement cover to document whether carbonation has reached or is approaching the reinforcing steel. The resulting data provides information that owners and engineers can use when considering corrosion risk and durability-related decisions.

Concrete cores are collected from structures for compressive strength testing to document concrete quality and strength.

These measurements provide data that engineers can use when considering structural capacity and load rating evaluations.

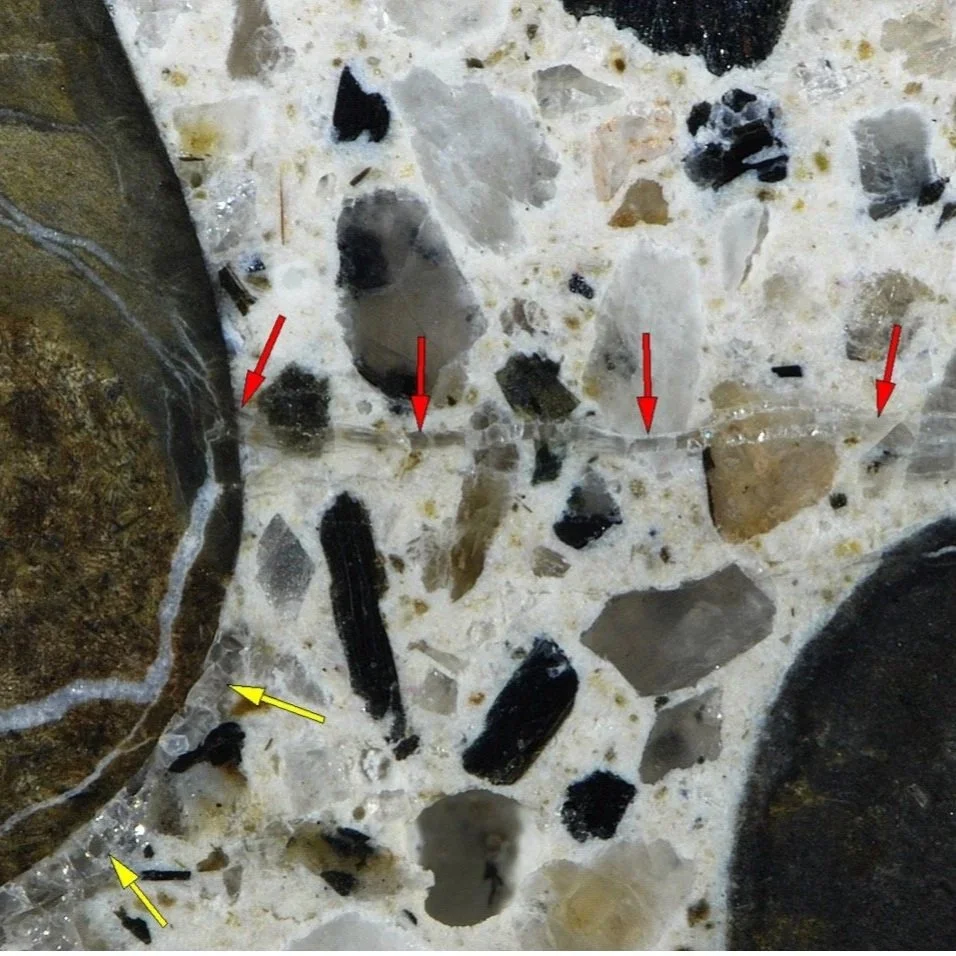

Petrography

Petrographic analysis is used to identify physical deterioration processes, such as freeze–thaw damage, as well as chemical deterioration mechanisms, including alkali-silica reaction (ASR) and sulfate attack within concrete. The analysis also documents the general properties and volumetric proportions of the concrete mixture used during original construction.

Petrographic examination provides detailed information on aggregate types, binder composition, and observed distress features present within the concrete samples.

Chloride Concentration

Concrete samples are collected from structures to measure chloride content and document the extent of chloride penetration within the concrete. Laboratory testing is used to quantify chloride concentrations at various depths relative to the reinforcing steel.

The resulting data provides information on the presence and distribution of chlorides within the concrete and can be used by engineers to assess corrosion-related considerations. Chloride concentration data is commonly used by engineering teams as input for durability evaluations and service life modeling of reinforced concrete structures.

Compressive Strength

Experience You Can Rely On

Founded in 1994, NDT has built a reputation for delivering reliable data, practical insight, and responsive service on technically complex projects. Our team combines decades of field experience with advanced testing technologies to produce results that are clear, defensible, and actionable for engineers and owners.